![]()

More and more people love to become more beautiful, and also more and more people love to join in the line of lash business.

Here are many types of false lashes on the lash market, which help girls and women get stunning eye makeup looks.

Lash extensions are the alternatives to strip lashes, so are you curious about how to create lash extensions?

Last Friday, we went to our lash manufacturer to learn the production process of making mink lashes and lash extensions.

So let’s get started!

Here is the lash extension manufacturing process in our lash extension manufacturer.

Raw material

What material is used to manufacture lash extensions?

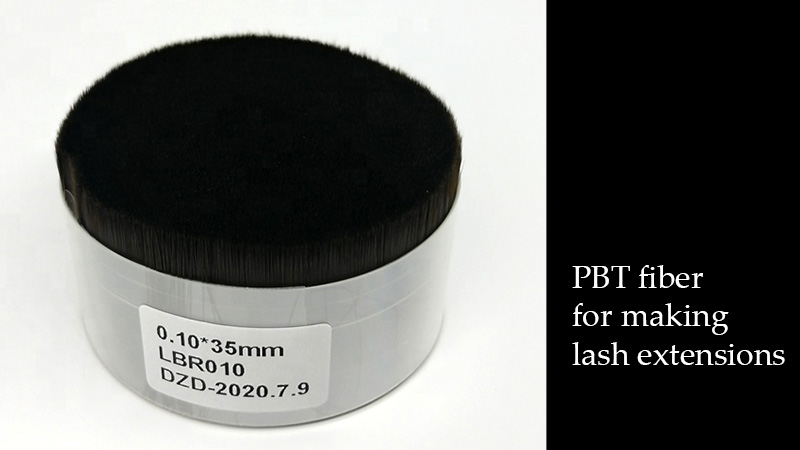

Compared with the mink lashes, (mink lashes are made of real mink fur) the raw material for making lash extensions is synthetic plastic fiber.

Here are many different materials on the market, including silk material, human hair, Polybutylene terephthalate, Korean PBT etc.

We use the top-rated PBT fiber filament for making lash extensions, with a smooth and silky texture, comfortable to touch.

And the PBT fiber can be designed with different diameters, different surface textures, such as matte, silky; and also soft and natural feeling to make natural lash extensions.

The PBT fiber has a strong persistence to the high temperature, waterproof and sweatproof, so it is important to retain long-lasting duration.

And the raw material PBT fiber can be varied as follows:

- Different diameters: The diameter of the raw material for making lash extensions can determine the thickness, dense of the finished lash extensions. And we have raw material varied in diameters, to make thick, thin, volume (minimum volume, medium volume, and maximum volume) lash extensions. And popular diameters are range from 0.02mm to 0.25mm.

- Different textures: Matte, silky, natural, thick, etc, you can choose the texture as your desired.

- Different colors: We have different colors of the raw material for manufacturing lash extensions, and red lash extensions, brown, orange, pink, is popular on the market.

So the first step for manufacturing the lash extensions is to select the raw material.

Shaping PBT fiber

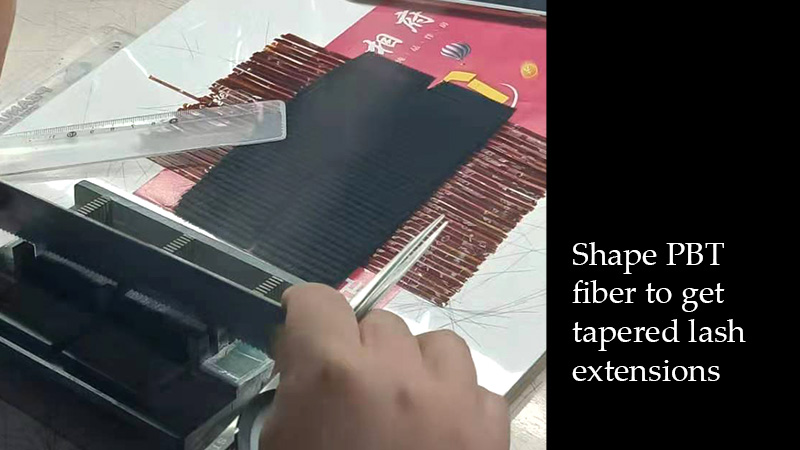

This step is similar to the step of making mink lashes, we need to use the lash mold to filter the PBT fiber hair to shape the styles of lash extensions.

The lash artist will use the lash tape to adsorb the PBT fiber, to get the lash extensions styles, with different lengths, thicknesses.

The experienced lash makers use the ruler to press the tape (the special for lash extensions, different from the adhesive wide tape for doing lash extensions to eyelids), and then the tape will paste the PBT fibers with the line shape.

It is important to get the first piece of the taped lash extension, and then repeat the working process to get the same taped lash extension styles.

Then place the taped lash extensions one by one, layer by layer.

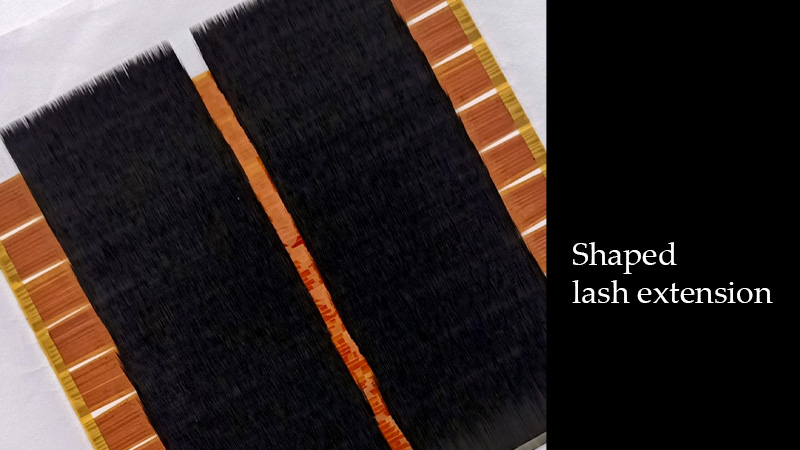

These are the taped lash extensions above and then go to the next step.

Cutting

The taped lash extensions have two parts, similarly to making mink lashes, and then we need to cut off the half without shape to keep the shaped lash extensions.

Use the iron rod or something heavy to knock the stainless steel rule to cut up the taped lash extensions into two pieces, and keep the shaped half to be the semi-finished lash extensions.

Rolling

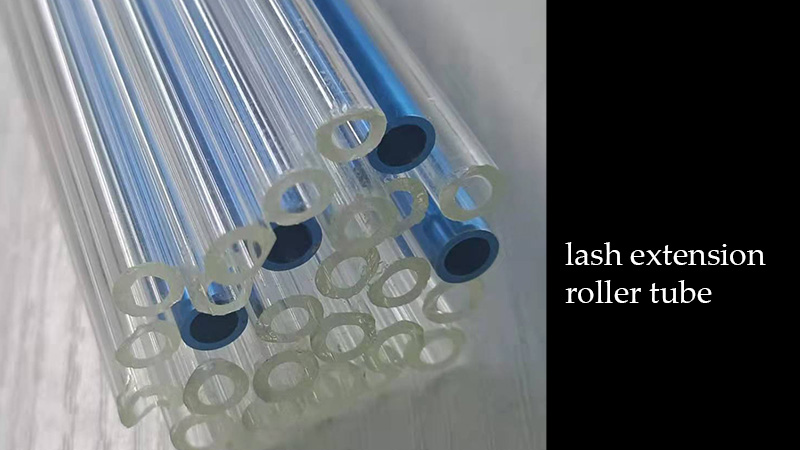

Then it is time to roll the semi-finished lash extensions, here we can use the stainless steel tube or glass tube, with different diameters to create different curls for lash extensions.

The tube with a bigger diameter can be used to create small curls, to get many flat lash extensions; otherwise, a small diameter is for bigger curls.

And the length of the roller tubes is the same, for 4 slices of lash extensions. And then keep the rolled lash extensions for 4-5 hours to remain the curls.

Then use the scissor to divide the combined lash extensions into slices, and cut off the extra tape of two tips of the semi-finished lash extensions.

Installing

The last step is to install the finished lash extensions and adhere the lash extensions on the background card, row by row, then we will get them done.

Here are something that can be customized:

- Background paper: The background paper in the lash extension case can be customized, print your private label, eyelash logo, and print your graphic patterns.

- Lash extension rows: The size of the lash extensions background paper can be customized, based on how many rows of lash extensions you want to place.

- Lash extension specifications: You can get your desired lash extensions, according to your wanted curls, thicknesses, curls, lengths, and also colors.

- Lash extension packaging: We have different materials for lash tray cases, you can choose plastic, acrylic, etc.

Final thoughts

We have our own lash manufacturer to design lash extensions according to your requirement, please feel free to contact us if you are interested in the lash extensions.