![]()

Hey, everyone!

Wearing false lashes is a strong method to help us get stunning eye makeup, fast and easy.

And are you curious about how lashes are made?

Today I share with the production procession of the lash manufacturer, how to make mink lashes, step by step!

We all the people in our company went to our lash manufacture today, and see how mink lashes are made.

Here are the steps:

Selecting the mink fur

As we all know that mink lashes are made of mink fur, and we need to select the mink fur at the very beginning.

The quality of the raw material can determine the quality of mink lashes.

Before making mink lashes, we need to prepare the mink fur as the raw material, and top-rated mink fur has a smooth and silky texture.

The mink fur is so soft, I feel like the fluff when I touch them, so comfortable.

At the very beginning, we need to select the best mink fur, as the raw material to make mink lashes.

To control the quality with the strict standard.

Welcome to watch the video to see how mink lashes are made by the lash manufacturer.

And let me share with you guys how mink lashes are made step by step in the following.

Lash Molding

Then we need to use the lash mold, made of stainless steel, to help us shape the mink fur into different lengths.

We need to put the sheaf of mink fur into the lash mold, and then make the mink fur in good trim, without any flying mink fur.

The steel rule with regular sawteeth can filter the mink fur to be lined with different lengths, for making mink lashes with different styles.

The lash mould is different for different lash styles, yes, one lash mould for one style.

We are the leading lash manufacturer based in China, with rich experience to create over 500 different styles of lash strips, which means we have over 500 sets of lash molds to help us work out the fashionable lash with the styles you desire.

The lash workers use the strip adhesive tape to adsorb the mink fur and set them in line to get the lash strip pieces. They place these raw materials mink fur layer by layer, like the way shown in the image.

Cutting

Then it is time to layout the tapped mink fur, to get the styled lash style. It is skillful to organize the tapped mink fur to combine the designed lash styles, you can see that we need to layout the finished lash style using many different semi-hand lash strips tapped by the adhesive tape.

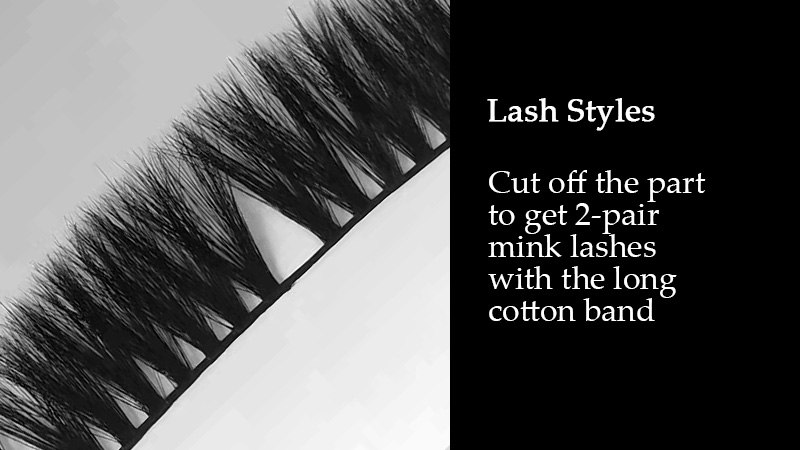

Then there are two parts of mink fur lash mold, one part is the mink fur we will get, you will see there is a black cotton lash band installed, and the other part is useless, we need to cut it off.

The shaped part of mink fur, installed with the black cotton band is the mink lashes we will get.

It is the combined mink lashes, 2 pairs of mink lashes are combined by one strip of the black cotton lash band.

Rolling

So it is time to roll the lashes, to get the desired curls.

We use the steel steel pipe to roll mink lashes and the steel is designed with different diameters. The small stainless steel pipe is used to roll mink lashes to get big curls, bigger curvature for bigger curls. And the stainless steel pipe with a small diameter is useful to make dramatic mink lashes with a 3D effect, and the stainless steel pipe with a big diameter is designed to create much more flat mink lashes with small curls.

Then we lash artists will steam the rolled mink lashes for 4-5 hours to get shaped mink lashes with curls. The mink lashes will get great curls after the steaming process, and the curls will stay in the good shape, without any transformation after cooling.

Separating

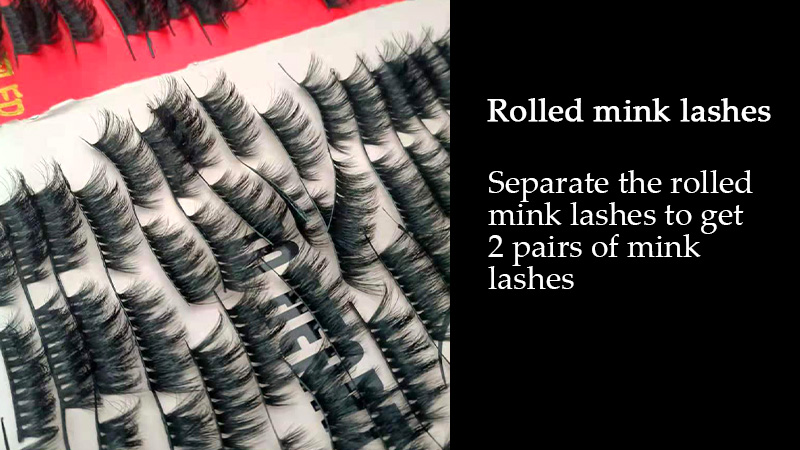

After the steaming process, the curls of mink lashes will be shaped, and we need to place the stainless steel pipe with rolled mink lashes in the cool place, until the mink lashes get dry, without being wet at all.

Then remove the mink lashes from the stainless steel pipe, and separate the combined mink lashes to get 2 pairs of mink lashes. The length of one stainless steel pipe is used to roll 2 pairs of mink lashes. So we will get the 2-pair mink lashes combined with a long black cotton lash band.

And we need to use the scissor to separate mink lashes, to get 2 pairs of finished mink lashes.

PS: Cut off the extra part on the tip of the mink lashes, from the front of the mink lashes to the end.

Installing

After the strict quality inspection process, it is time to install the finished mink lashes with the lash tray.

We will place one pair of mink lashes on the lash tray before the packaging process. And we have the regular transparent plastic lash tray, with 2 shapes.

And we can place the mink lashes on the custom lash tray, according to your requirement.

We can custom the lash tray, with different colors, shapes to match your lash box packaging.

The lash process is the mink lashes packaging, and we have many different types of lash boxes, including paper lash boxes, magnetic lash boxes, drawer lash boxes, and etc.

Well done, you will get your desired mink lashes from here!

Final thoughts

Up to now, our lash factory has over 500 different lash molds to make over 500 lash styles for you, and then we can create a new lash style for you too.

We have our own lash manufacturer, with big ability to create new lash products. Please don’t be hesitate to share with us your ideas on your lash creation.

We can work out any image on your lashes!

In order to support a small lash business, we can print your private label, lash brand, and eyelash logo on the lash packaging box.